Welding UHV assembling and testing

More than thirty years of experience in TIG welding, mainly in stainless steel are put to the service of customer’s projects. SAES RIAL Vacuum is equipped with 5 TIG welding machines to weld stainless steel, aluminium and its alloys, copper.

SAES RIAL Vacuum has four qualified welders according to UNI EN ISO 287-1:2007 (UNI EN 287-1:1993 + A1:1999). Their qualification covers thickness range from 0.15 mm to 25 mm on stainless steel AISI 304L – 316LN; they have gained a great experience in TIG welding most of all on stainless steel with or without filler material. The quality of TIG special welding joint is assured by application of internal qualification procedure; resulting welding parameters are formalized in pWPS according to UNI EN ISO 15609-1:2006 (UNI EN 288-2:1993 + A1:1999). pWPS are then qualified according to UNI EN ISO 15614-1:2005; (EN 288-3:1993 + A1:1999. The qualification of welders and welding process is always released by a third part company. SAES RIAL Vacuum also has a great experience in welding for cryogenic applications.

Bake out facilities

SAES RIAL Vacuum is equipped with a special vacuum oven in which is possible to perform bake out (up to 350°C), RGA and outgassing measurements. The max inner diameter is 800 mm for a length of 900 mm. If the size of vacuum components exceeds maximum available space, heating jackets (or wrapped tapes) all around the chamber are used. The heating elements can be arranged and split in order to have different area of the chamber driven by independent thermo-controllers. It allows to improve the temperature distribution along a chamber with asymmetric cross section. Bakeout, RGA analysis, leak test at high temperature, base pressure and outgassing rate measurements can be executed in-house by a vacuum furnace or by heating tapes. In both cases the vacuum vessel is directly connected by metal sealing to a separated analysis chamber.

Test equipment is briefly described in the following:

- Dimensions of furnace: ID 800mm, length 900mm

- Heating: in furnace by infra-red lamps, in air with heating tapes and heating jackets

- Baking temperature is controlled by thermocouples; thermocouples are also used to cross-check the effective temperature directly on items

- Vacuum pumping system: it is composed by a cryo pump, a turbomolecular pump and a dry rough pump

- Cooling: Furnace equipped with external jacket and doors water cooled

- PC interface and data-recording

- Quadrupole mass spectrometer Pfeiffer Vacuum PrismaTM 80 QMS 200 with mass range 1-80 amu, sensitivity 10-12 mbar

- Cold cathode vacuum gauge sensitivity 5×10-11 mbar

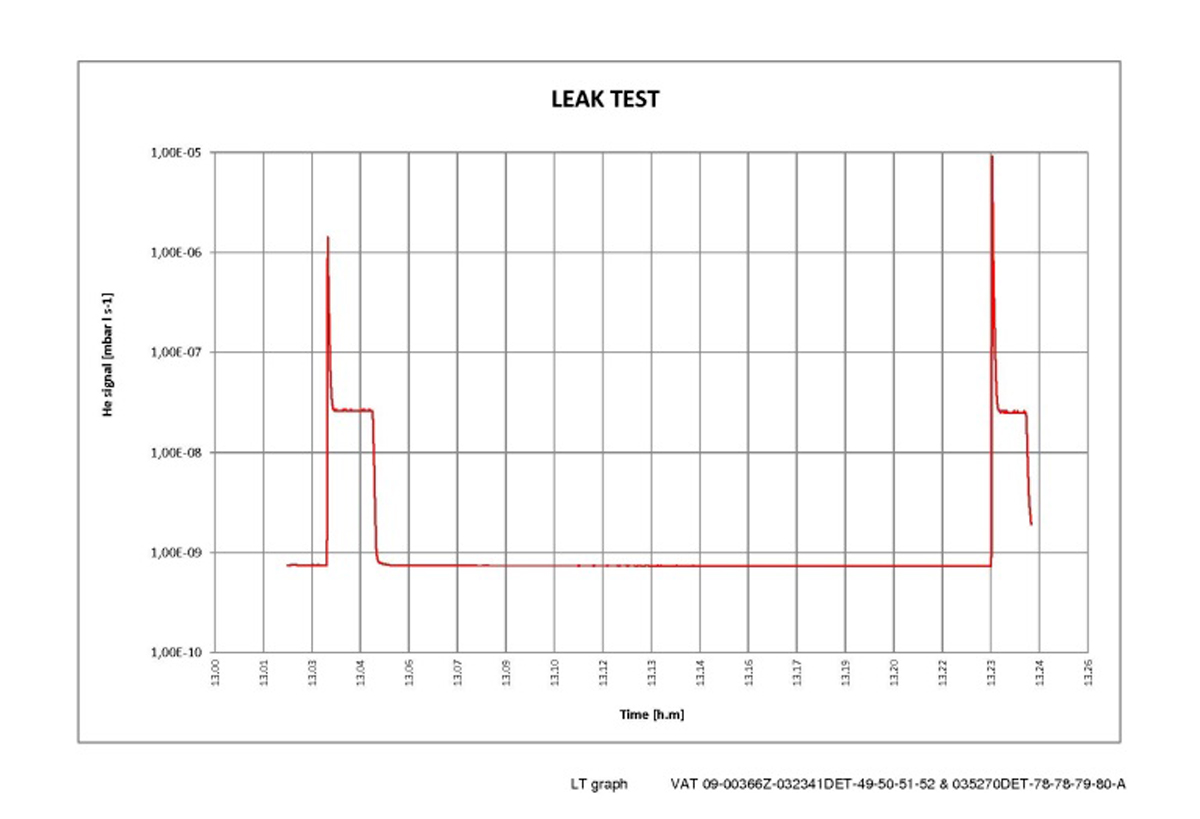

Leak testing

Leak testing procedures are common knowledge inside the company and daily applied by five technicians experienced with UHV compatible working procedures. Following vacuum pumping, helium leak detectors and vacuum gauges are available at that moment:

- N.1 Leak detector type ASM 142 ALCATEL

- N.1 Leak detector type L947 VARIAN

- Turbo pumps, turbo-molecular and molecular pumps ALCATEL, PFEIFFER-BALZERS various models and years of delivery;

- Primary pumps RIAL, ALCATEL, PFEIFFER-BALZERS, EDWARDS, VARIAN;

- DRY pumps RIAL, ALCATEL, PFEIFFER-BALZERS, EDWARDS, VARIAN, LEYBOLD;

- Cryo-pumps CTI, various models and years of delivery;

- 2 Cold cathode vacuum gauges;

- 2 Pirani vacuum gauges.

SAES RIAL Vacuum is equipped with two clean areas, not classified as clean rooms. They are isolated from the rest of the workshop by a double anti-dust door. For welding operation is also available another closed area of 15 m2 located inside the main workshop where welding can be executed in clean condition.