For the industry

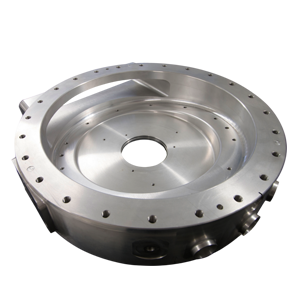

SAES RIAL Vacuum produces a wide range of coating and process chambers, that assure the best work results, both for integrity and reproducibility of outcome and for absence of any contamination.

Coating and process chambers

The surface functional properties of a material can be changed by adding a thin evaporated or sputtered layer of a different appropriate element. For example, optical properties of lenses such as light transmission, reflectivity or polarization can be changed by deposition of a suitable layer of a thin film. This finds application either in high tech scientific experiments where light has to be properly manipulated or in commonly used glasses for eye ware. Also in this case, as the coating process is carried out in a vacuum environment, vacuum chambers with suitable cleanliness and vacuum integrity are required to ensure product reproducibility and quality.

Food and beverage

SAES RIAL Vacuum regularly serve the food and beverage industry providing dosing and loading chambers and systems. The UHV expertize is key to ensure extremely high level of cleanliness and surface smoothness as required by this industry