For accelerators

Accelerators are very complex machines made of a large number of high or UHV compatible chambers and components. All surfaces exposed to vacuum must possess the proper surface roughness and be suitably treated and cleaned in order to minimize the outgassing load on the pumping system. During the accelerator operation, vacuum surfaces are generally also exposed to radiation, either in the form of charged particles or electromagnetic radiation. This significantly enhances the gas desorption from surfaces (dynamic outgassing) and/or bring significant heat loads on the irradiated surfaces. Appropriate material selection, surface treatment and effective cooling is therefore key is many applications. Very low magnetic permeability is also required for vacuum chambers which are immersed or close to strong magnetic fields. Moreover, to comply with the requirements of the physics experiments, accelerator vacuum chambers and devices may require very complex designs and shapes with tight tolerances. Special machining , including EDM techniques, the adoption of careful welding and appropriate UHV handling and cleaning procedures are therefore a must for this application.

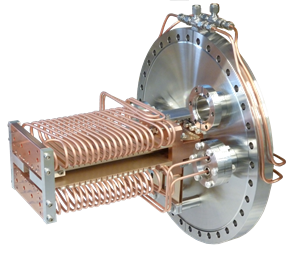

RF Bellows and absorbers

These devices are key either in light sources and colliders. Manufacturing may require a combination of several machining technologies, including EDM deep or wire erosion. Welding expertize is also key to ensure performance and long term reliability during operation and under high thermal load and mechanical stresses. In both areas, SAES RIAL Vacuum has developed unique design and manufacturing expertise.

Undulators

In vacuum Undulators are insertion devices usually part of a synchrotron storage ring, or components of a free electron laser. Their main task is to produce a very intense and concentrated X ray radiation which is guided through beamlines to the experimental stations for experiments in various scientific areas. Significant pressure burst can be generated during the operation due to the radiation induced gas desorption from the vacuum chamber surfaces. To mitigate this aspect, it is important to devote great care to the surface finishing of the undulator chamber, as well as to its cleaning and the vacuum processing. The use of UHV pumps with large sorption speed can be important to keep the pressure below acceptable limits during the undulator operation. With this respect, the use of NEG pump, which deliver very large pumping speed in a much smaller package than other pumps may be advantageous to ensure undulator faster conditioning and lower ultimate pressure. NEG technology is also key to ensure the achievement of low pressure conditions in narrow gap in air undulators, which would not be efficiently pumped by conventional lumped pumps mounted at the ends of the chamber. In the case of narrow gap undulators, the NEG is distributed in the shape of a thin film deposited onto the internal surface of the chamber.

SAES RIAL has the manufacturing expertise to supply either in vacuum undulator chambers or out vacuum , narrow gap, NEG coated undulator chambers .

Special vacuum chambers

To confine and accelerate particles to very high energy, in synchrotrons, FEL or colliders, the vacuum envelope has to be shaped to perfection. High quality construction materials (e.g. aluminum and aluminum alloys, stainless steel, titanium, ceramic, metal/ceramic joint etc. ) have to be used. Precise machining, high tolerances, surface finishing, handling, cleaning and assembling technologies are required. Clean environment where to assemble, test and apply metrological check are also necessary. SAES RIAL can provide chambers made of different materials, degree of surface finishing, cleaned to UHV standards and suitably vacuum conditioned. SAES RIAL Vacuum Technical Department can also provide support to the customer during the chamber design activity, suggesting technical solution or carrying out modeling activities to improve the product design.