Design, thermal and vacuum modeling

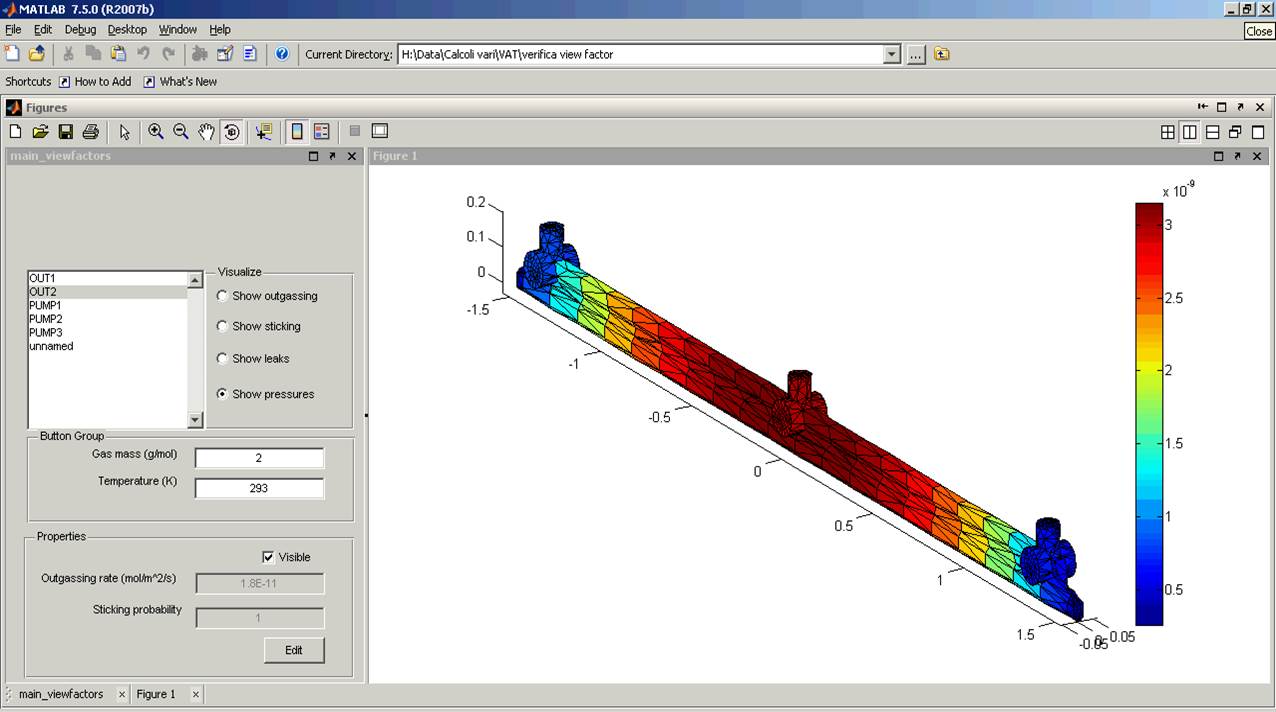

The expertize in vacuum technology and the modeling capabilities can be put at the customers service starting from the design stage, to drive the process in the most effective way. In this respect, SAES RIAL Vacuum can provide recommendations or suggest technical solutions to improve the design or facilitate the manufacturing and testing of the product. Through the use of several mathematical tools , such as ANSYS, MOLFLOW+, VASCO, LTspice and others it is possible to simulate mechanical, thermal and vacuum properties of a component or a device to predict its performances or to identify potential critical issues already at the design stage and during the development steps. This allows to identify the key parameters and their impact on the product performances and possibly find remedies through modification or re-design of the product or a different selection of components or the manufacturing processes. This finally results in a faster development process which saves time but also provides a more reliable output.