Fine machining according to vacuum standards

One of the key expertise of SAES Rial Vacuum is EDM (Electro-discharge Machining) fabrication by sink and wire erosion. More than 20 EDM machines are available, which can perform different tasks on a variety of materials used in vacuum technology ( steel, copper, aluminum, refractory metals, graphite…) as summarized below:

- 14 Wire EDM

- 4 DIE-Sinking EDM

- 3 Hole Drilling EDM

- 28 Milling, turning and grinding machines

- Laser Marking

- 9 TIG/MIG/Microplasma and Laser Welding

These equipment, along with more than 20 years’ experience gathered in the EDM machining of complex and technically challenging components for the high tech industry and research facilities provides confidence that technical problems can be properly addressed and successfully solved. The total EDM working area covers a surface of 400 m2.

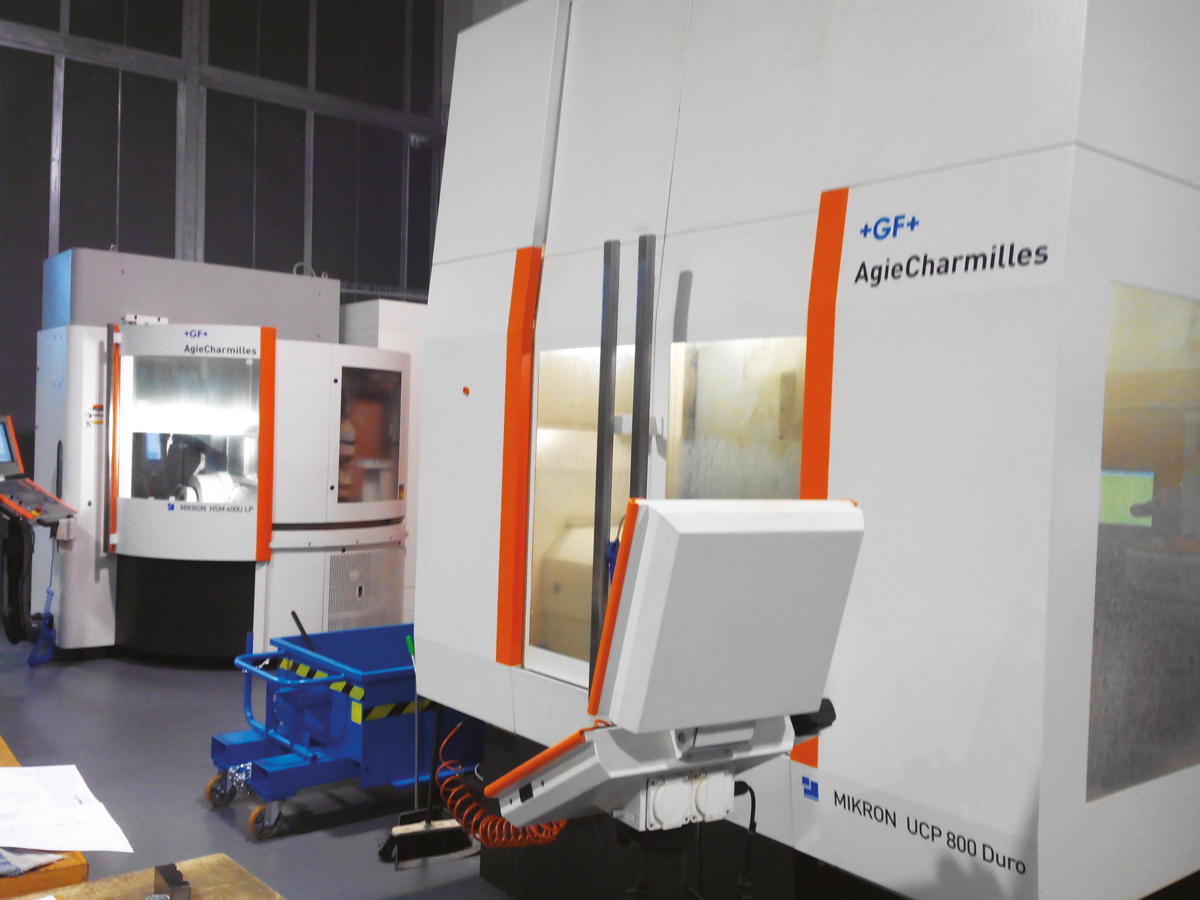

A large park of high precision mechanical machines for CNC milling, grinding and turning of constructional materials for vacuum applications complements the EDM range.

Micro-drilling, CNC fine milling, turning, grinding and laser welding are carried out according to customer’s specifications. All the cutting fluids are compatible with high vacuum applications (without heavy organic lubricants, water miscible).

The vacuum chambers and component production place is divided in two different parts : the stainless steel sheet working area ( 700 m2) and the welding and assembling area (5600 m2). This last sector is preserved from dust and strict cleaning procedures are followed to keep it suitable for UHV assembling activity. EDM and finer machining are carried out in two nearby separate plants.

Metrological area ( 70 m2) and a vacuum test area (60 m2) are kept in a clean state with humidity and temperature control. These quality rooms are separated from the manufacturing area.

The following Quality Control equipment are available for metrological control and assessment of the chambers realization.

- MITUTOYO QM-Height 600

- ZEISS CONTURA & DURAMAX

- FARO ARM EDGE with laser scanning

- ETALON DERBY

- OGP FOV

- MITUTOYO SJ-400

Surface cleaning facilities

SAES RIAL Vacuum has knowledge and technical equipment for cleaning components with unique characteristics regarding material, complexity of surfaces as well as low outgassing and low particle generation. Our processes are optimized to fulfil requirements for optical industries and accelerator technology. The cleaning process and the applied cleaning agents are suitably adapted to the different materials and are validated by the customer. A 7 m long bath is available to clean to UHV standard very long chambers and pipes. A crane is available in the cleaning area and suitable to lift weight up to 500 kg