Design and modeling of vacuum systems

The Technical Department is able to develop and manage UHV, cryogenic and superconductivity projects. SAES RIAL Vacuum is equipped with software for vacuum systems design and analysis, FEM analysis and computation, pressure profile determination in complex systems, as well as project planning.

Technical Department can address the following tasks:

- 3D design for vacuum chambers and systems

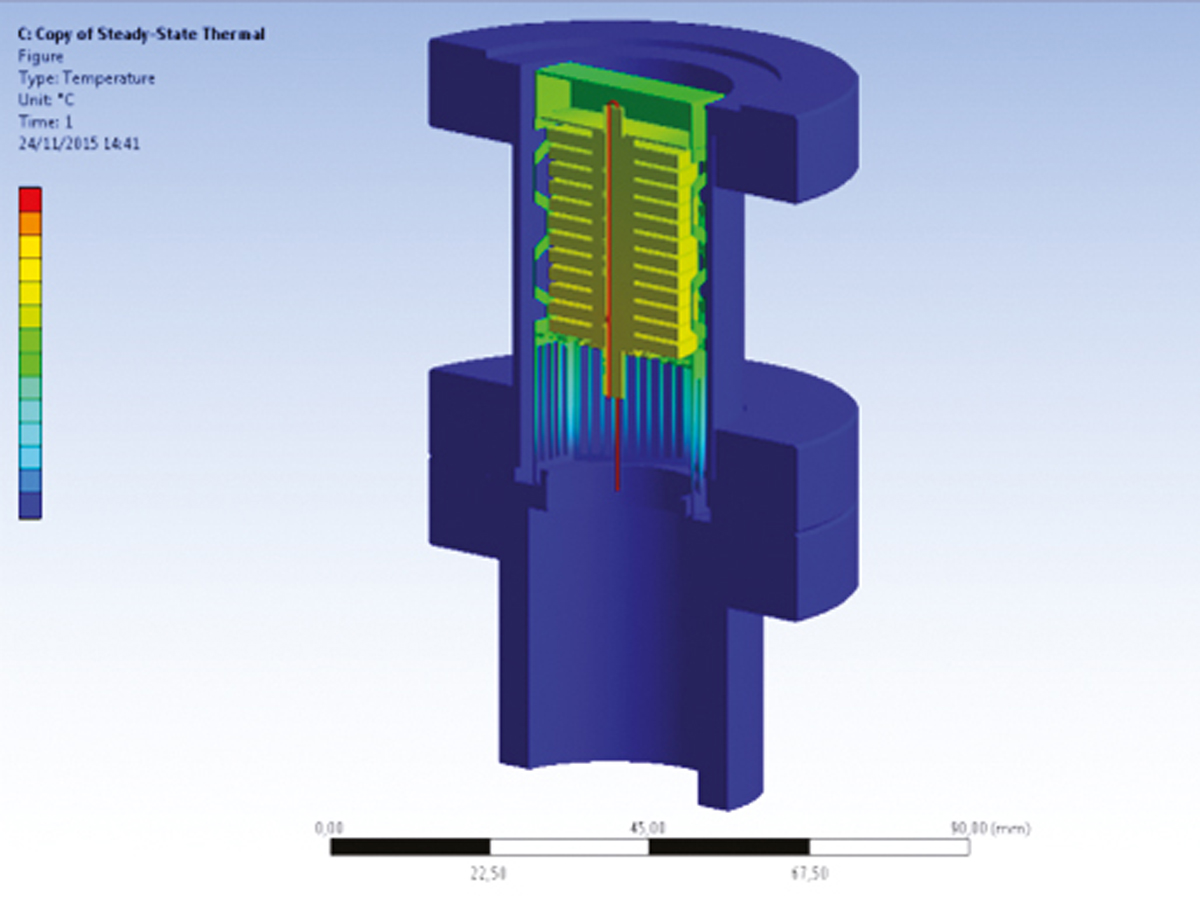

- Thermal exchange calculation

- FEM and thermo mechanical simulations analysys (ANSYS, COMSOL)

- Computational fluid dynamics (CFX)

- Molecular flow in complex vacuum systems (Molflow/SIMULATorr)

- UHV special motion feedthroughes and in vacuum multiaxial manipulation

- UHV cinematic solutions with compatible actuators

- In vacuum cooling and heating

- Beam diagnostic

These resources can be made available for customers during the initial design stage or for performance evaluation, product optimization or as a support for testing and qualification.

SAES RIAL Vacuum can also benefit from and leverage on the broader R&D capabilities of SAES Group which includes metallurgical and testing laboratories for materials preparation and characterization, Scanning Electron Microscopes and EDX analyzer, X-ray diffractomer, outgassing and RGA facilities, UHV characterization benches, thin film getter deposition facilities and a fully equipped chemical laboratories. System automation (SCADA, PLC architecture, OPC client server integration), electronics and engineering services are also available.